How Is the New High-Temperature Heat Pump Revolutionary?

It is one of the first in France. In 2022, Dametis installed cold production on an industrial site with innovative heat recovery using cutting-edge technologies. In addition to electrifying steam needs, this installation improves performance, reduces environmental impact and responds to the site’s desire to move towards an ideal factory model with electrified processes. Yann Balem, design office engineer at Dametis, tells us more.

“After an audit carried out in 2021, an industry in the food industry made two observations: the need to renovate its cold installation and to change one of its boilers. All to save energy,” says Yann Balem. To meet these expectations, Dametis presented a project including the replacement of the steam boiler, the installation of a new production of chilled water with optimized heat recovery, and the association of an ultra-heat pump. innovative.

What’s the benefit of a high-temperature heat pump?

A heat pump for hot water can reach up to 80°C. The one installed by Dametis and its partners can reach 95°C. Its experimentation and implementation within a site are a first in France. “By reaching such a degree, it gives us the possibility to supply processes, such as milk pasteurization, which requires water above 85°C,” details Yann Balem. “It is also planned for this pump to supply clean-in-place (CIP) processes with the reheating of acid and soda tanks.”

A Concept with Economic and Environmental Benefits

To achieve this, the heat pump’s cold source needs to be powered. This may seem paradoxical, however, “to produce cold, we are obliged to reject heat,” recalls the project manager from Dametis’s side. “Just like the heat pump, the refrigeration system is a thermodynamic system. We produce cold and heat at the same time.” Heat recovery from the refrigeration unit has been optimized to reach 55°C. This loop at 55°C feeds the heat pump’s cold source, allowing it to produce water at 95°C on a second network.

French electricity mix is one of the most decarbonized in Europe, compared to some other countries, notably Germany. Indeed, it is thanks to the large share of nuclear and hydroelectric power in France that we emit fewer greenhouse gases per kilowatt-hour produced compared to fossil fuels.

For example, for the dairy industry project, the heat pump allowed at least a 15-fold reduction in greenhouse gas emissions from processes previously powered by steam produced from gas, according to ADEME’s indicators.

Indeed, according to a study conducted by ADEME (source = ADEME Carbon Base), 1 kWh of French electric power consumed emits 0.0407 kgCO2 equivalent, while 1 kWh of gas emits 0.227 kgCO2 equivalent. A much larger amount of greenhouse gases is emitted to produce 1 kWh of gas. For reference, in Germany, 1 kWh of electricity = 0.357 kgCO2e.

There are also operational benefits. “In the project, we also created a network at 55°C,” he explains. “This made savings, but it has a double interest because we eliminated steam exchangers producing hot water at medium temperature, such as domestic hot water, and by doing so, we reduced the cost and time spent on maintaining steam distribution systems.”

*ADEME: Agency for the environment and energy management

An Amortized Investment

Dametis proposed this turnkey project. The startup took care of all aspects, from overall design, establishment of the engineering dossier, and management of subcontractors, ensuring the proper execution of the work. Dametis experts also supervised the budget, schedule, and structured third-party financing solutions.

“We also commit to performance. If we don’t achieve the savings initially announced, we incur penalties.” Thus, Dametis undertakes to maintain optimal performance for several years. With this approach, savings of around 25% are expected on gas, while the site will benefit from a reduction of around 20% in its carbon footprint.

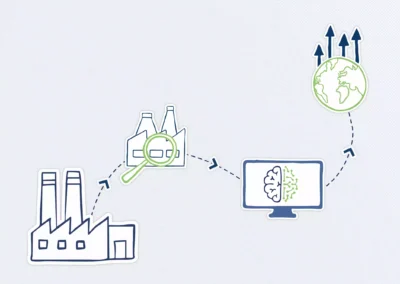

For this, the MyDametis software is a considerable asset. This tool allows mapping and centralizing all information related to water, energy, and environmental discharge management. With this business platform, you know your energy, water, and material consumption, but you can also model flows between equipment based on parameters to find the optimal setting of installations and manage installation performance over time.

If this innovation has emerged in a food processing company, all industries may need to acquire it. “With water at 95°C, we are capable of covering many needs,” emphasizes Yann Balem.