Energy efficiency plan: what are the challenges for industrial players?

Summary

1. The challenges of energy efficiency for industry

2. 2024 Energy Efficiency Plan: definition

3. Who is impacted by the energy efficiency plan?

4. How is energy efficiency applied in industry?

5. What actions should be adopted?

6. The 2024 Energy Efficiency Plan: outcomes and developments

7. How to implement an energy efficiency plan in industry?

The challenges of energy efficiency for industry

The industrial sector is a significant emitter of greenhouse gases, accounting for 20% of national CO2 emissions according to Réseau Action Climat. Including construction, it is considered the third-largest emitter of CO2 in France, following transportation and agriculture, as reported by the Ministry of Sustainable Development.

Do you want support in decarbonizing your industry?

Reducing greenhouse gas emissions is a critical challenge for the industrial sector, especially to achieve arbon neutrality by 2050 it is also essential for navigating winters smoothly, even in a context where Russian gas deliveries have nearly stopped, helping to avoid shortages and power cuts.

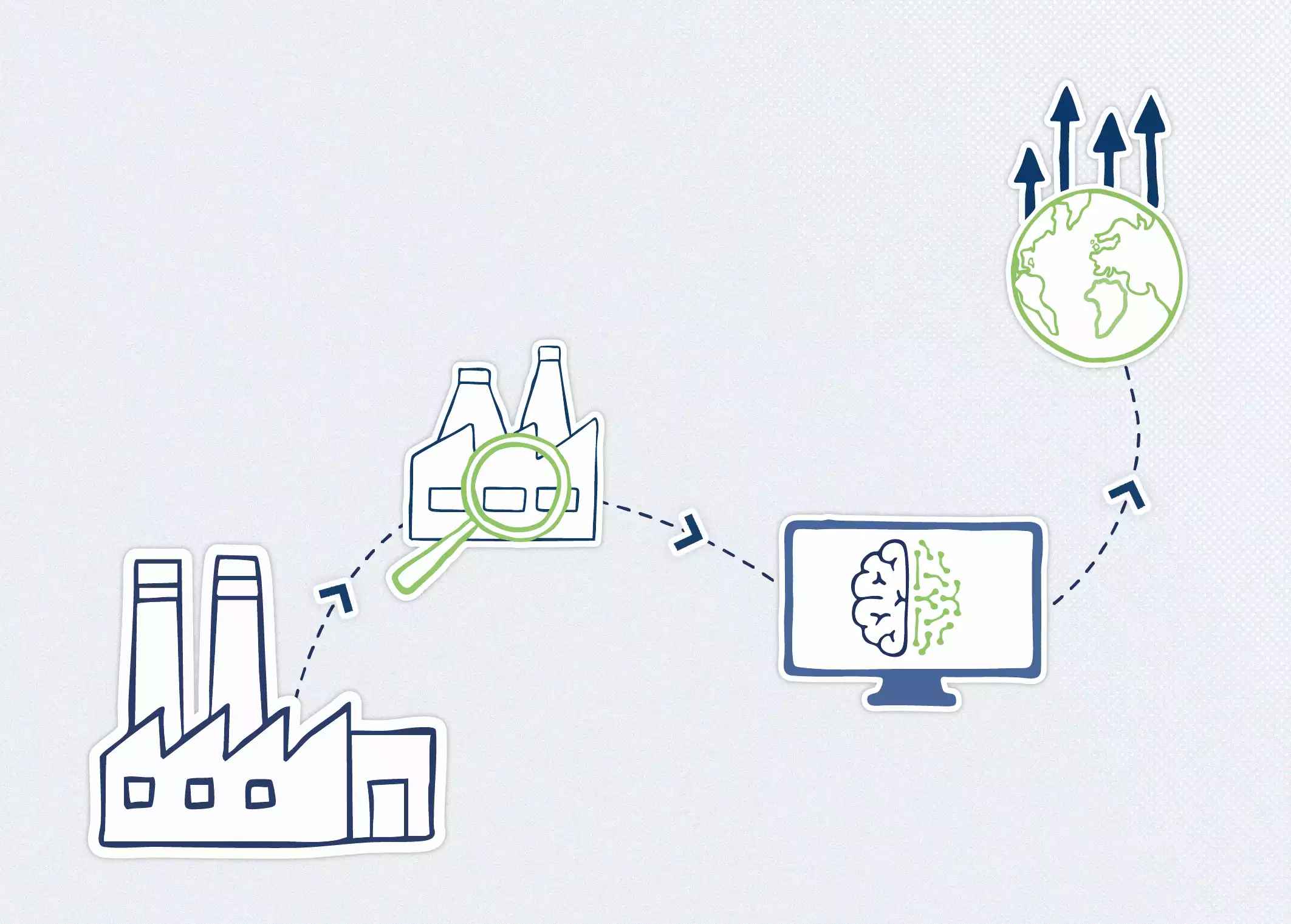

One solution is to move toward energy efficiency: a voluntary approach aimed at reducing energy consumption (gas, electricity, fuel, etc.). Energy efficiency not only helps transition away from fossil fuels but is also beneficial for the environment and the bottom line—lower energy consumption means lower bills.

The goal is to reduce energy use while maintaining the same production levels. To support industrial players in this process, the energy efficiency plan offers clear guidance.

The 2024 energy efficiency plan: definition

The French government has set a target to reduce energy consumption by 10% by 2024 compared to 2019 levels. This serves as an initial milestone toward the ultimate goal of carbon neutrality by 2050.

To achieve this, the government provides general guidelines in a document called the energy efficiency plan. This plan was announced by the President of the Republic in 2022 during the July 14 speech, highlighting the need to anticipate shortages linked to the war in Ukraine.

Who is affected by the energy efficiency plan in industry?

We are all affected by the energy efficiency plan, regardless of our status or sector: individuals, local authorities, businesses, public establishments, the tertiary sector, industry, housing, transport, digital, sports, and more. Energy efficiency must be tailored to each sector. .

Currently, having an energy efficiency plan is only mandatory for the 120 largest companies in France. For the rest, the measures are based on common sense and goodwill. It is especially in the interest of industrial players to implement energy efficiency actions, as they are among the first to be affected in the event of electricity shortages or rationing.

How is energy efficiency applied in industry?

Here are the key measures from the energy efficiency plan to implement in the industrial sector:

- Conduct an energy audit to identify energy loss points and potential optimization areas.

- Implement Energy Management and a comprehensive strategy to reduce consumption.

- Invest in devices that enable quick energy savings: smart sensors, sealing of various networks, thermal insulation of heating networks, etc. It may also be beneficial to join the PACTE Industrie program, which trains and supports industries in their decarbonization efforts. PACTE Industrie, which trains and supports industries in their decarbonization efforts.. L’aide peut, entre autres, subventionner des investissements tels que ceux évoqués ci-dessus.

Dametis supports you in conducting energy audits and setting up an energy management system!

For example, the implementation of an energy management system at Toshiba by Dametis led to a 50% reduction in energy consumption within one year. Thanks to our EMS software, My Dametis, teams are now autonomous in managing and continuously optimizing their energy usage.

What actions should be adopted?

We’ve seen some energy efficiency measures from the energy efficiency plan designed for the industrial sector, but other measures are common across all sectors:

Save energy in buildings:

- Follow temperature guidelines:

- When spaces are in use: limit heating to 19°C in winter and air conditioning to 26°C in summer (and ideally, avoid using air conditioning altogether).

- When spaces are not in use: limit heating to 16°C (if the space is unoccupied for 24 to 48 hours) or 8°C (if unoccupied for more than 48 hours).

- Use a building automation and control system (BACS): Intelligent management will significantly reduce energy waste. For example, this system automatically lowers heating during unoccupied hours, adjusts lighting based on outside brightness, etc.

- Renovate industrial buildings: This includes upgrading boilers, insulating attics and walls, replacing lighting with LEDs, and more.

- Insulate water networks/pipework: To prevent heat loss, for example, when a pipe passes through an unheated area.

- Maintain equipment, especially boilers and heat pumps: Regular descaling ensures they remain efficient.

Practice more sustainable mobility:

- Implement the sustainable mobility package (FMD) for employees: this can be used for purchasing a bicycle, reimbursing public transport costs, etc. It is exempt from social security contributions up to €800.

- Encourage public transport, carpooling, and cycling.

- Avoid unnecessary travel: prioritize videoconferencing when possible.

- Prefer train travel over car travel.

It is also recommended to choose partners and subcontractors who are actively engaged in energy efficiency efforts.

The 2024 energy efficiency plan: results and developments

Results in 2024

So, what are the first results of the energy efficiency plan in 2024? During the winter of 2022-2023, a 12% reduction in gas and electricity consumption was observed. The target has been achieved.

However, it is essential to continue our efforts and embed the measures of the energy efficiency plan in the long term. Experts estimate that we would need to reduce our energy consumption by 40% (compared to 2019 levels) to reach the targets set for 2050. Energy efficiency must become part of the daily routine for all French citizens, industries, businesses, local authorities, etc.

New Measures of the Energy Efficiency Plan Act 2

Following the initial results, the government has released the Energy Efficiency Plan Act 2. This new plan sets the goal of “making France the world’s leading industrial country to exit fossil fuels.” The aim of this new phase is also to promote long-term measures tailored to the summer period (while the first phase of the plan was more focused on the winter months).

Specifically, for the industrial sector, here are some new actions:

- Energy efficiency in transportation:

- For freight transport, enhance delivery optimization, particularly by using software to optimize routes.

- Encourage employees to drive at 110 km/h on highways (instead of 130 km/h) for business purposes. This would reduce greenhouse gas emissions and fuel consumption by 20%. More broadly, promote eco-driving training.

- Improve vehicle maintenance.

- The tax penalty on the heaviest and highest CO2-emitting vehicles has been strengthened.

- Transport expenses related to renting private bicycles can now be reimbursed by employers.

- The tax reduction for companies providing company bicycles to employees has been extended until December 2027.

- Encourage teleworking when possible to reduce travel.

- Energy efficiency in digital operations:

- Promote the purchase of refurbished professional phones, as well as the reuse of equipment.

- Encourage companies to train employees on best digital practices.

Evolution of the plan over the coming years

In the coming years, the energy sobriety plan is expected to continue introducing new measures to encourage the French population to reduce their energy consumption. On our side, we remain vigilant and will keep you informed if new state subsidies become available to support industrial players in their energy transition.

How to implement an energy efficiency plan in industry?

Here are the steps to follow to implement an energy efficiency plan in the industrial sector:

- Identify the main consumption areas through an energy audit.

- Raise awareness and train teams on best energy-saving practices.

- Building an action plan and implementing consumption optimization actions

- Measuring the impact of actions

- Continuous monitoring of consumption and identification of new reduction opportunities

Dametis supports you in implementing your energy efficiency plan.

As an industrial player, you have every reason to implement an energy efficiency plan. Here are some of its benefits:

- Reduce costs and increase margins

- Contribute to achieving carbon neutrality

- Take a step towards France’s energy independence and reduce the risks of shortages

Dametis will assist you in implementing this plan in your industry. We will start by conducting an energy audit, which will help us identify specific areas of energy loss and waste. We will then put in place measures to optimize your consumption, such as: Industrial refrigeration optimization, methanization, waste heat recoveryetc.Finally, to ensure you are autonomous in managing and optimizing processes on a daily basis, we will implement our EMS software, My Dametis. You will benefit from real-time advice from our energy managers, 7 days a week, 24 hours a day.